Since the introduction of the first moulding compounds based on Unsaturated polyesters, this class of materials has developed into a variety of high performance SMC & BMC composite solutions for a broad range of applications In view of their excellent features and benefits, these materials will continue to be used for many demanding applications.

1. Strength and stiffness

The combination of fibers, fillers and resin results in material systems with great stiffness and mechanical strength. The resin provides the ductility, durability and system cohesion. The fibers are largely contributing to strength and stiffness. Glass fibers, carbon fibers and combinations of the two are being used.

2. Part safety through great Fire retardance

Elevated resistance to fire and low smoke generation is important for many applications and markets. For obtaining this high flame retardency a number of additives can be used.

SMC & BMC do not contain any halogens or other hazardous flame retardants. Still they can be formulated having excellent FR properties, even at very low wall thicknesses.

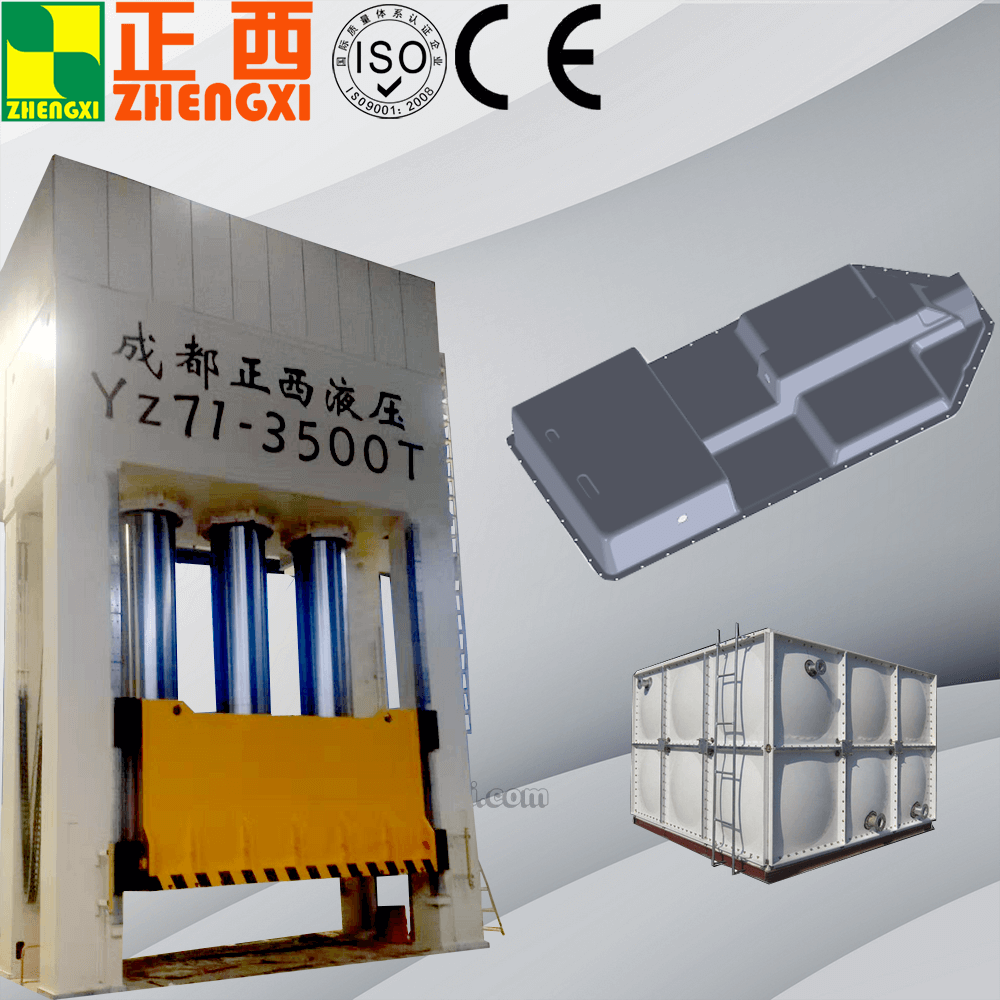

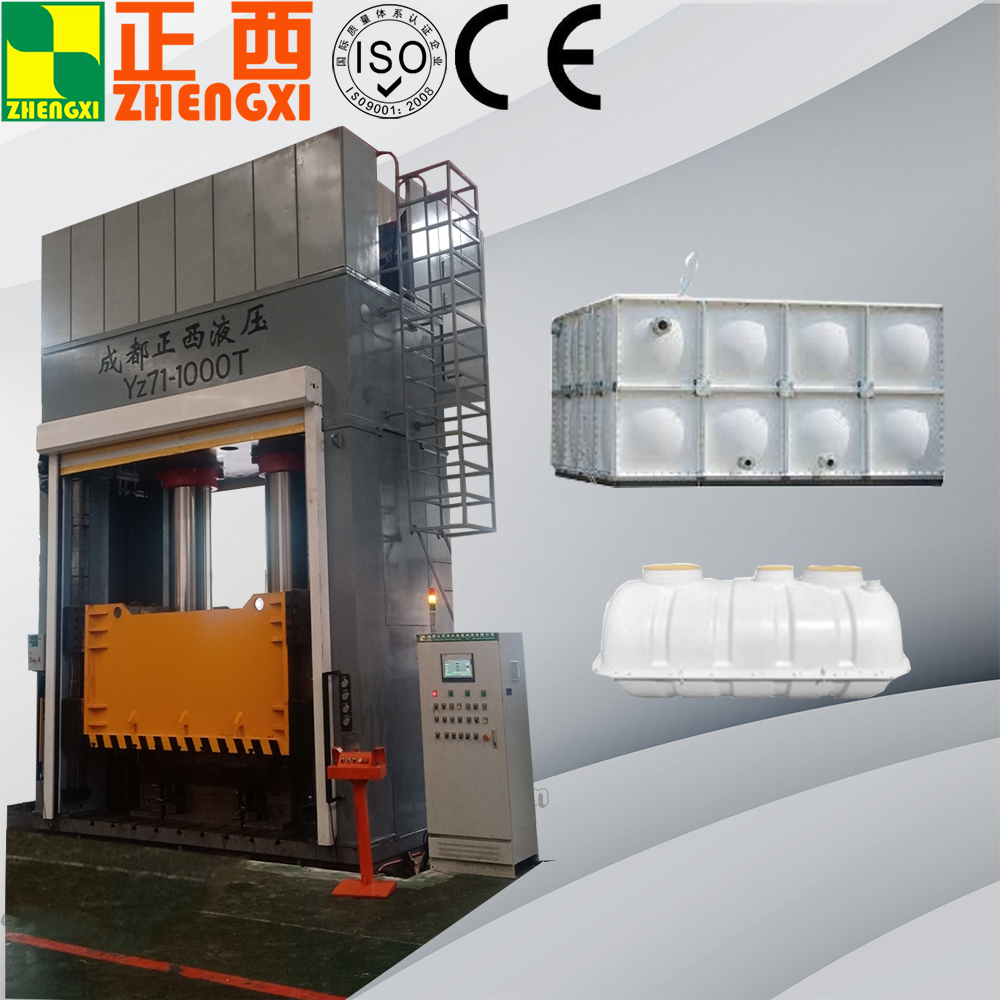

3. Weight reduction

For reducing Eco-footprint and fuel emission, SMC & BMC Composite solutions can enable manufacturing components with less weight. The mechanical properties of SMC & BMC Composite solutions help to easily replace a large number of metal parts by few composite parts.

4. Electrical performance

Excellent electrical performance is a main benefit of using thermoset materials in general.

SMC & BMC Composite solutions bring these excellent electrical properties, particularly electrical strength, water absorption and surface resistivity.

Despite of their excellent electrical insulation properties also materials with reduced surface resistivity and elevated conductivity are available.

5. Precision and predictability of dimensions

SMC & BMC are first choice solutions for substitution of high performance metal parts where high precision is obtained by means of post-machining processes. Tight tolerances can be produced directly without post operations, ensuring not only cost savings but also increased profitability.

As a main advantage compared to equivalent non- thermoset polymers, the ability to compensate shrinkage with special additives makes even most challenging part designs feasible. For parts with highest precision, materials with negative shrinkage (expansion) can even be used.

6. Great Class A surfaces

The ability to obtain excellent surfaces for online- and offline painting, as well as for parts metallization is a great asset of working with both SMC & BMC Composite solutions. superior surface aesthetics can be obtained through the unique technology to compensate the material shrinkage.

7. Resisting elevated temperatures

Many thermoset polymers are known for their excellent thermal resistance. Using specific resin systems thermal resistances up to 300°C can be achieved. From a technical view these materials can be superior to engineering thermoplastics and provide cost effective solutions especially in comparison to high performance thermoplastics.

For demanding engineering applications it is also crucial that the CTE (Coefficient of Thermal Expansion) is close to the CTE of metals and ensures dimensional stability over a wide range of temperatures.

8. Low emissions

Interior parts in many end use markets require low emission materials (e.g. car interior parts). Minimization of hazardous or uncomfortable emissions and smell is desired.

Also in lighting systems the headlamp reflectors must be free of any emissions in order to avoid fogging, that will reduce lighting performance.