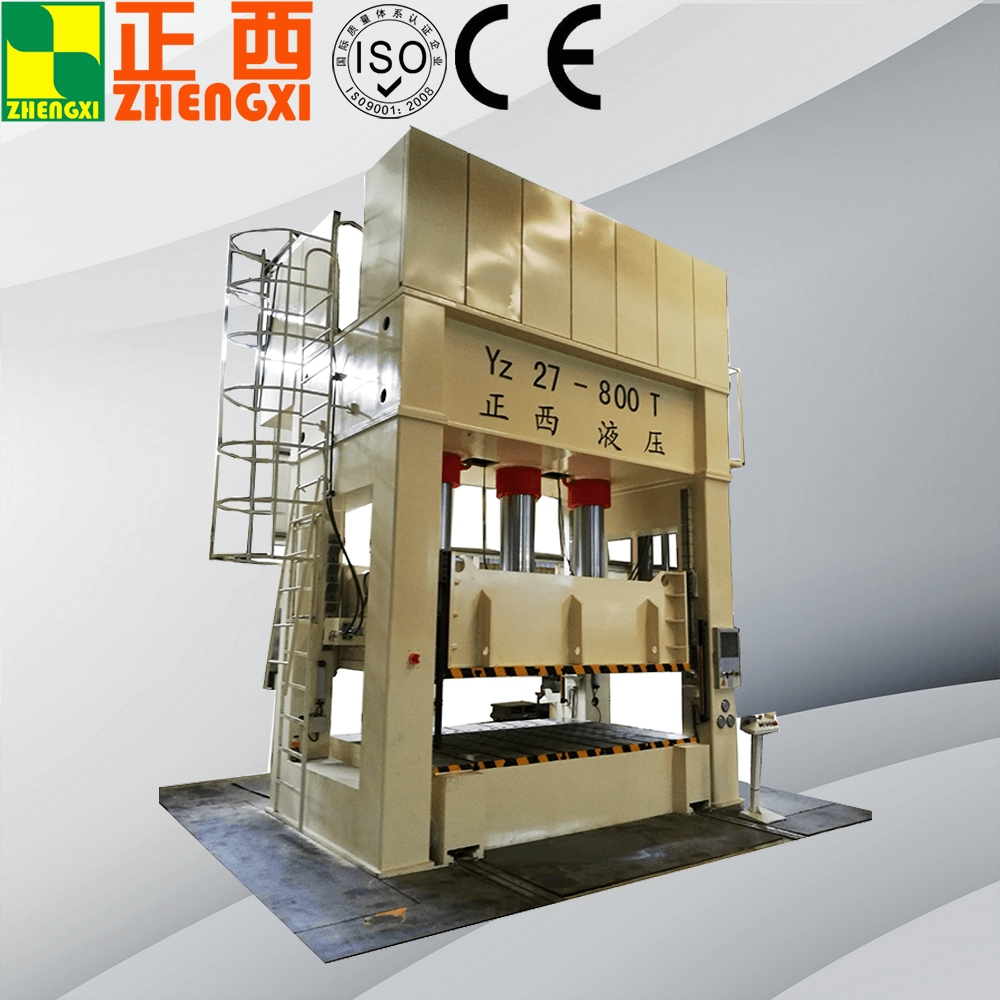

800T Deep Drawing Hydraulic Press

The press machine is mainly suitable for sheet metal part processes such as stretching, bending, crimping, forming, blanking, punching, correction, etc., and is mainly used for quick stretching and forming of sheet metal.

The press machine is been designed as assembled H-frame which has best system rigidity, high precision, long lifetime and high reliability, and is used for pressing sheet metal parts and can meet the demand of production at 3 shifts/day.

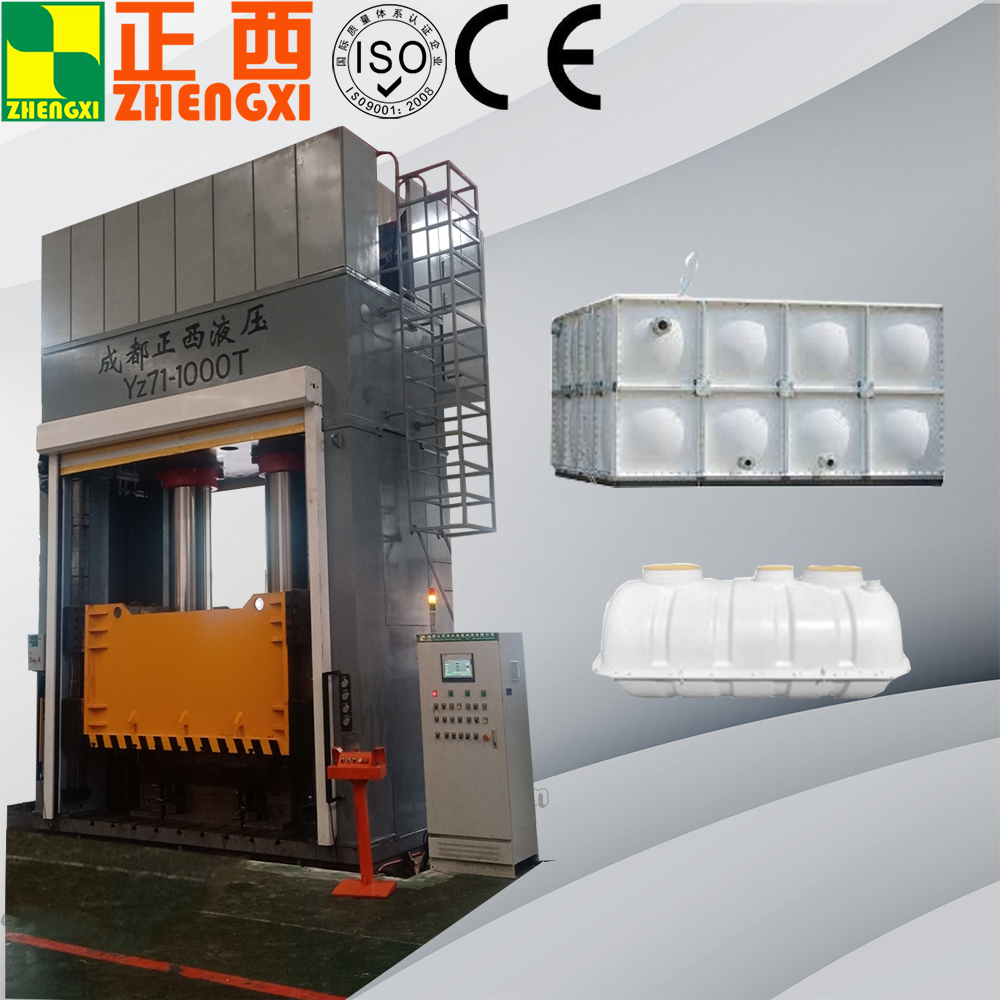

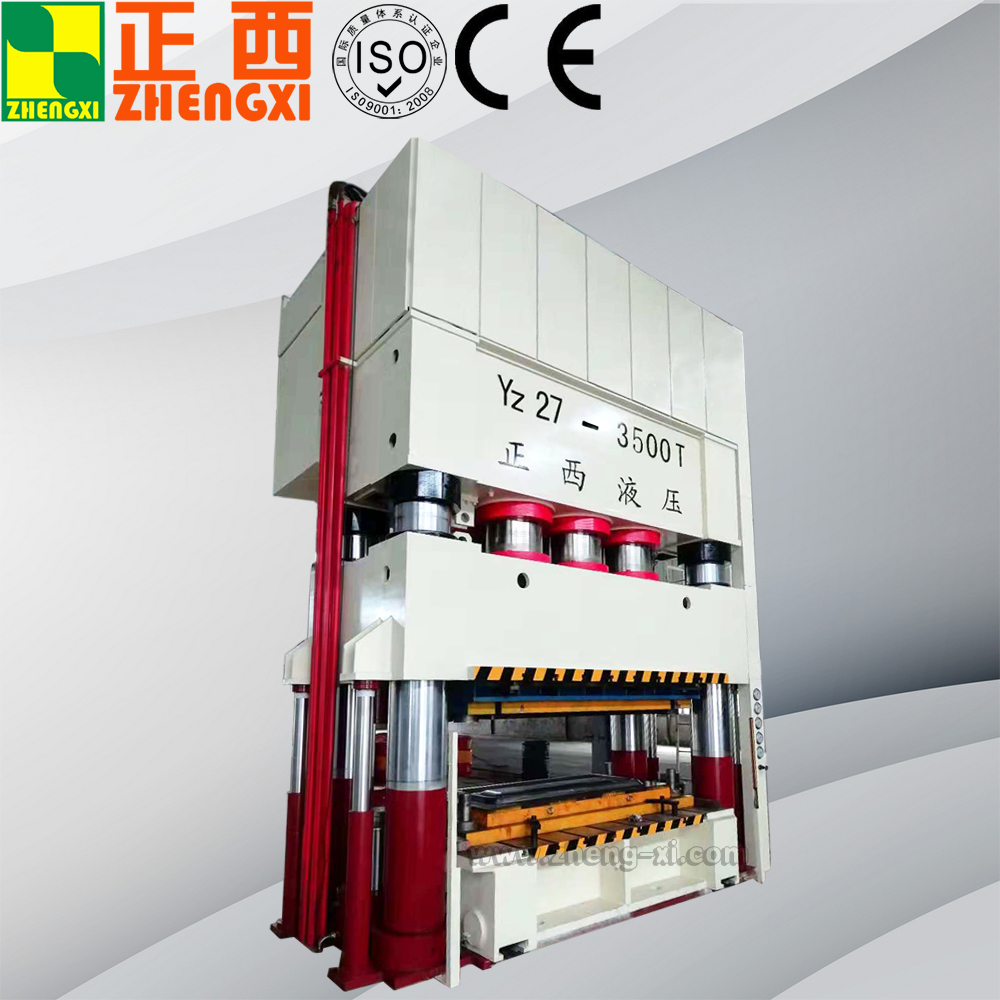

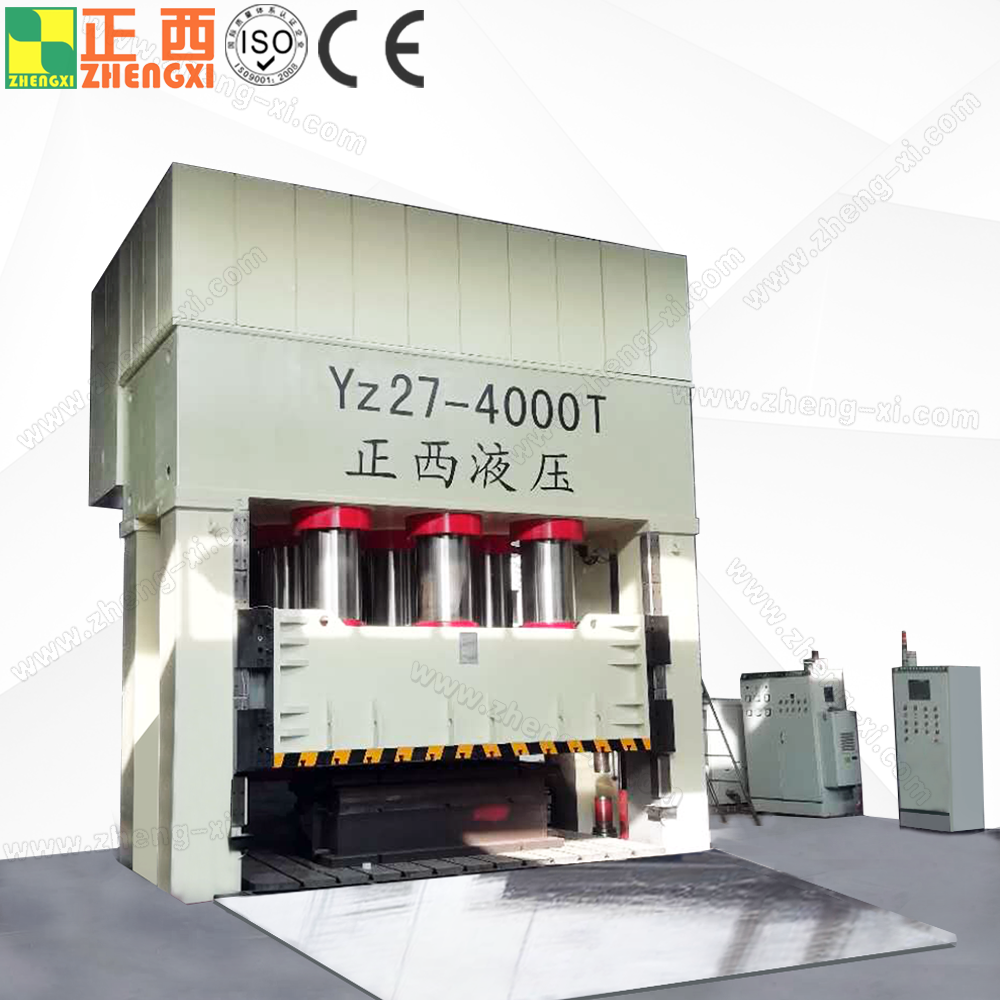

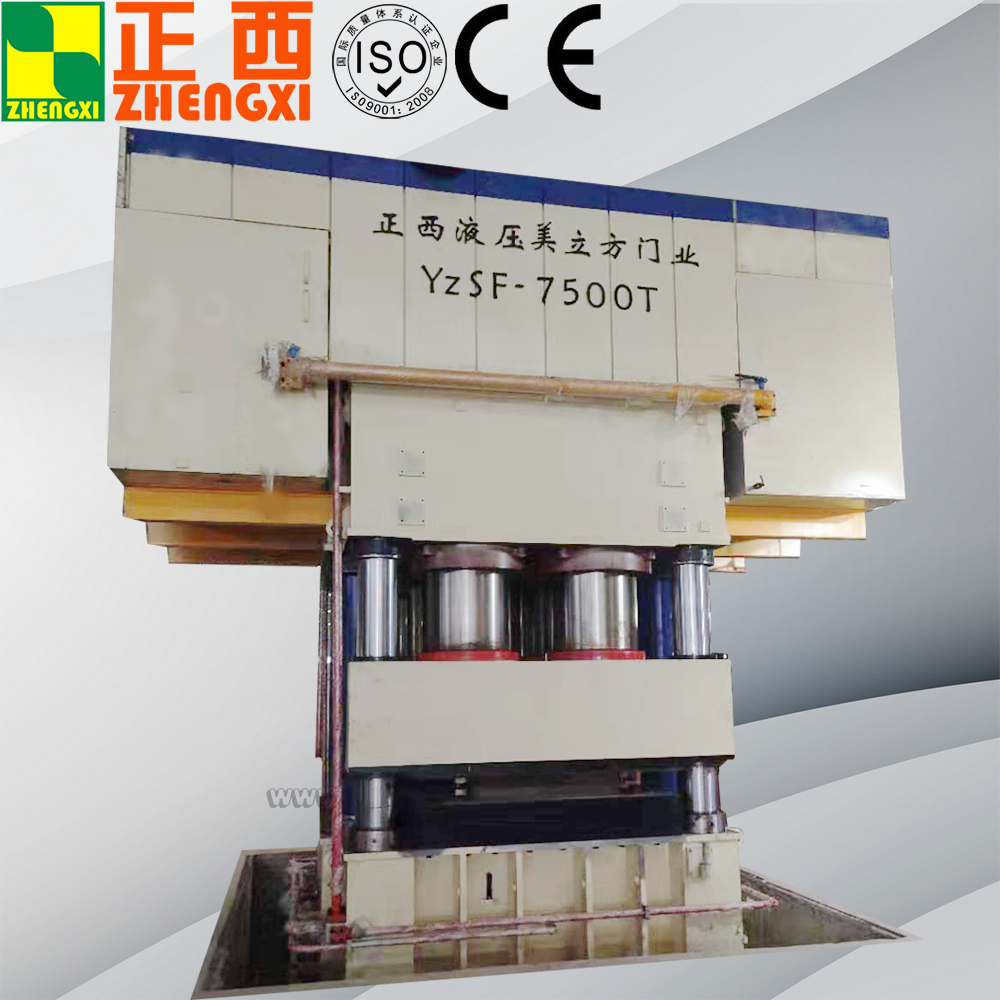

Machine Picture

Machine parameters

|

Name |

Unit |

Value |

|

|

Name of machine |

|

Sheet metal stamping hydraulic press |

|

|

Model |

|

Yz27SF-800T/250T |

|

|

Main cylinder pressure |

KN |

8000 |

|

|

Cushion force |

KN |

2500 |

|

|

Max. liquid pressure |

MPa |

25 |

|

|

Daylight |

mm |

1500 |

|

|

Main cylinder Stroke |

mm |

900 |

|

|

Cushion stroke |

mm |

350 |

|

|

Worktable size

|

LR |

mm |

3000 |

|

FB |

mm |

2000 |

|

|

Hydraulic cushion size |

LR |

mm |

1950 |

|

FB |

mm |

1350 |

|

|

Slider speed |

Down |

mm/s |

400 |

|

Return |

mm/s |

400 |

|

|

Working |

mm/s |

17-42 |

|

Hydraulic System

- Oil tank been set forced cooling filtering system(industrial plate-type water cooling device, cooling by circulating water, oil temperature≤55℃,make sure machine can steadily pressing in 24 hours.)

- The hydraulic system adopts integrated cartridge valve control system with fast response speed and high transmission efficiency.

- The oil tank is equipped with an air filter to communicate with the outside to ensure that the hydraulic oil is not polluted.

- The connection between the filling valve and the fuel tank uses a flexible joint to prevent vibration from being transmitted to the fuel tank and completely solve the problem of oil leakage.

Servo System

Servo System Composition

Advantages of Servo System

- Energy saving

Compared with the traditional variable pump system, the servo oil pump system combines the fast stepless speed regulation characteristics of the servo motor and the self-regulating oil pressure characteristics of the hydraulic oil pump, which brings huge energy saving potential, and the energy saving rate can reach up to 30%-80%.

Efficient

The response speed is fast and the response time is as short as 20ms, which improves the response speed of the hydraulic system.

Hydraulic Control System

The hydraulic system adopts integrated cartridge valve control system with fast response speed and high transmission efficiency.

All motors, pumps and pipes are fitted based on advanced Europe technology to achieve shock-resistance.

ZHENGXI Hydraulic Press is an ISO:9001, CE certified company, we offer you various hydraulic press machine and other series of composites molding press. Contact us and get a detail on our machine.

-

Item No.:YZ27

-

Payment:T/T,L/C

-

Product Origin:China

-

Color:As Per Customer's Requirement

-

Shipping Port:Chongqing Port, Shanghai Port

-

Min Order:1 Set

-

Lead Time:About 3 Months